This case study explores the journey of a cutting-edge FPGA system through a rigorous thermal management evaluation. Conducted by E-Sharp AB, the study aimed to ensure the system’s reliability and performance under heavy computational loads. Through meticulous testing and analysis, the project provided valuable insights into the system’s cooling capabilities, highlighting areas for improvement and setting a benchmark for future evaluations. The testing also resulted in software changes that improved performance in high ambient temperatures.

Background

In the ever-evolving landscape of technology, the FPGA system stands as a testament to innovation and engineering prowess. This sophisticated piece of hardware is designed to handle heavy computational loads with remarkable efficiency. However, the significant heat generated by the system’s FPGAs and other complex electronic components must be properly managed. If not, overheating and potential system failure could jeopardize the reliability and performance of the FPGA system.

Recognizing the critical importance of effective thermal management, the client partnered with E-Sharp AB to conduct a comprehensive evaluation of the FPGA system’s cooling capabilities. The goal was to ensure that the system could operate safely and efficiently under heavy loads without succumbing to overheating. This project, spearheaded by Arvid Hjortsberg, a Systems Engineer at E-Sharp AB, aimed to provide valuable insights into the thermal dynamics of the FPGA system and to verify its design in terms of cooling capacity.

The project was divided into two main stages, with the first stage focusing on real-world testing to validate the system’s cooling capabilities. Prior to this project, simulations and calculations had been performed on parts of the system, but no full-scale testing had been conducted. The need for a real-world test scenario was paramount to ensure safe operation margins and to verify that the system design could handle the thermal challenges posed by heavy computational loads.

Solution

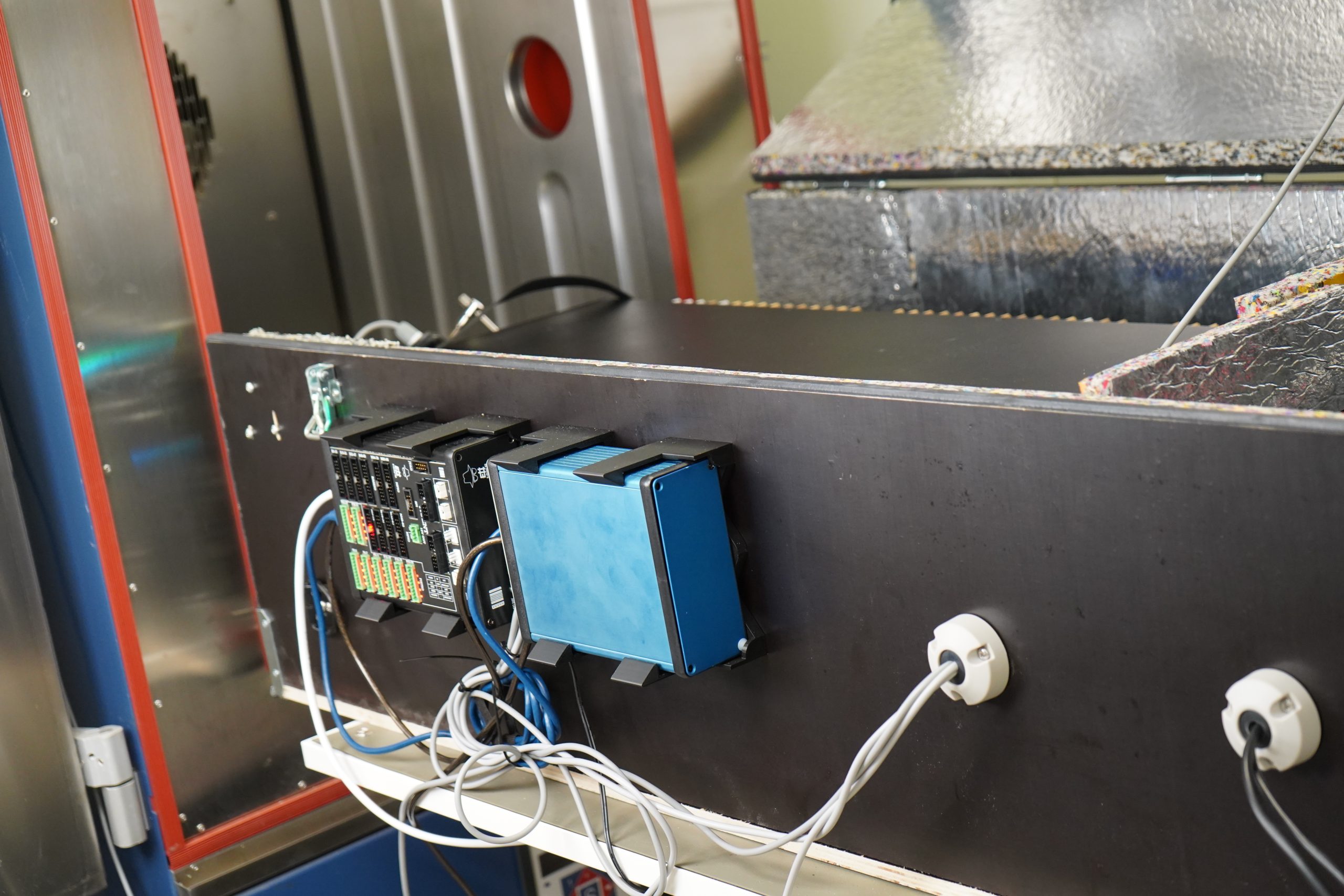

The approach taken by E-Sharp AB was methodical and thorough, involving a series of well-defined steps to achieve the project’s objectives. The first step was to construct a test environment that could accurately simulate the conditions under which the FPGA system would operate. This involved designing a climate chamber with three main sections: the active thermal management chamber, the passive intake chamber, and the passive exhaust chamber. The FPGA system was placed in this environment, with air being blown through the system using eight fans to remove the generated heat.

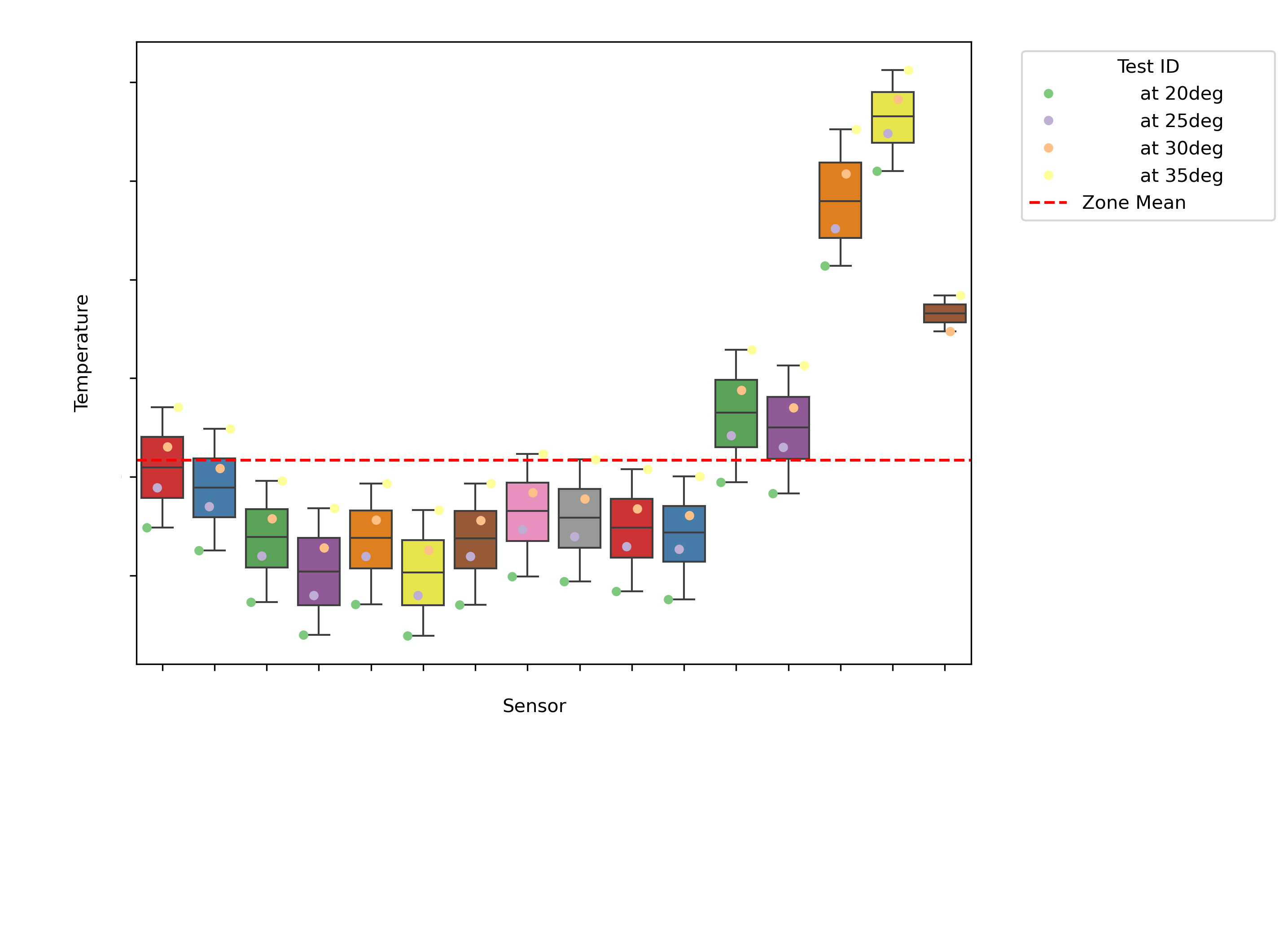

The testing process was meticulously planned and executed. The FPGA system was subjected to various test scenarios, with parameters such as ambient temperature, the number of FPGAs loaded, system orientation, and fan setup being varied. Data was collected from multiple sources, including the system’s integrated temperature sensors and external measurement equipment. This data was then processed and analyzed using data analysis tools in Python to extract meaningful insights.

The data collected during the tests was extensive and detailed. Each test run involved collecting data from the system’s log output and the test environment, with variables such as temperature, voltage, current, and fan speeds being monitored. The data was then processed into a coherent dataset, with values being averaged and interpolated to ensure accuracy. This dataset formed the basis for the analysis, which focused on identifying patterns, risks, and anomalies in the system’s thermal behavior.

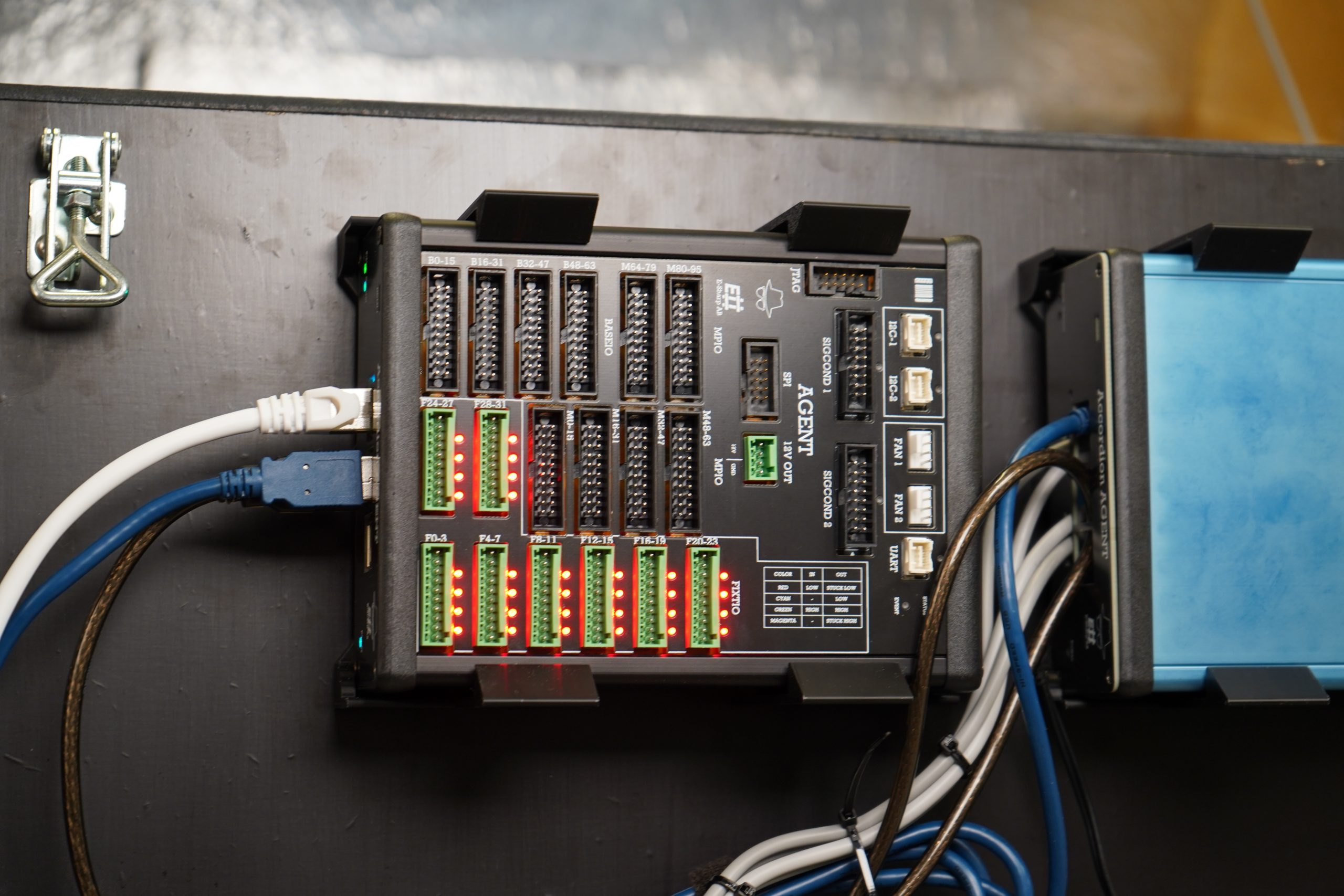

A crucial part of the data collection process involved the use of the Accordion Agent and the Accordion2Excel add-in. The Accordion Agent is a versatile data acquisition system used for a wide range of applications, including test interfaces, automated machine control systems, and data logging. In this project, the Accordion Agent was used as the logging device, outputting the measured data in an Excel file using the Accordion2Excel add-in. This add-in allowed for real-time plotting of the measured data, which was collected with timestamps and saved as a CSV file using a VBA script. The measurements from the test environment included temperatures, pressures, and set values for the test chamber.

Results

The results of the thermal management evaluation provided valuable insights into the FPGA system’s cooling capabilities. The tests revealed that the system could handle heavy loads at ambient temperatures within the tested ranges, with the system running close to its specified temperature limits at the higher end of this range. The system did experience overheating at temperatures exceeding the temperatures within the testing range, highlighting the importance of maintaining appropriate ambient temperatures during operation.

One of the key findings was significant temperature differences between some of the zones, with one zone consistently running hotter than the others. This was attributed to the additional heating from a specific components heat exhaust, which contributed to the higher temperatures observed in the zone. The tests also showed that the system’s thermal dynamics were influenced by the number of FPGAs under load, with the FPGAs further away from the air intake experiencing higher temperatures.

In conclusion, the thermal management evaluation of the FPGA system was a critical step in ensuring the reliability and performance of this advanced piece of hardware. Through meticulous testing and analysis, E-Sharp AB and the client were able to verify the system’s cooling capabilities and identify areas for improvement. This project not only provided valuable insights into the FPGA system’s thermal behavior but also set a benchmark for future evaluations of similar systems.

Often, we develop a specific module or even a specific form factor (test fixtures) to your needs. But we also have standard modules for a wide range of measurement applications.

Know the feeling? Don’t worry, E# can help you.

We have design capabilities to redesign your product to use components that are available. Perhaps we even fix one or two weaknesses in the process. Depending on your need, we can also verify and validate the new design for you and offload your design team from spending time on the legacy stuff.

Perhaps you need to gather all tangled cables into a tidy connector board or find a way to interface your product with test equipment. We do that too. We can take on design and manufacturing for your test boards so you can focus on other things.

Contact us with your needs and we promise to find a way forward. No job is too small for us.