How E-Sharp partnered with a global leader in silicon design to develop and implement NPI test solutions for complex FPGA systems

A leading global provider of silicon design and verification solutions engaged E-Sharp to design and deliver turnkey test solutions for their advanced prototyping systems. This initiative was a core part of the customer’s New Product Introduction (NPI) process, ensuring that every new board design would be validated before integration into production. Through deep collaboration, technical ingenuity, and a relentless focus on quality, E-Sharp built a scalable infrastructure that accelerates product introduction and safeguards system integrity.

Background

In the world of silicon design, few companies have the global reach and reputation of this customer. Their high-performance prototyping systems are the backbone of pre-silicon validation for some of the most complex system-on-chip (SoC) designs in the industry. These systems are not just powerful; they are intricate, modular, and built to scale. A single unit can contain up to a dozen FPGAs, each connected through high-speed interfaces and dense signal networks.

With such sophistication comes a formidable challenge. The boards that make up these systems are marvels of engineering, carrying tens of thousands of signals and relying on precise mechanical and electrical integration. Assembling a system is a time-consuming process, and any faulty board introduced into the build can derail the entire effort. The stakes are high, and the margin for error is razor-thin.

To maintain their standards of excellence and support the successful introduction of new products, the customer required a test strategy that would be integrated into their NPI process. The goal was to catch faults early—before boards were assembled, before systems were powered, before time was lost. This meant developing a test approach that was comprehensive, fast, scalable, and traceable. For this, they turned to E-Sharp.

Solution

E-Sharp approached the challenge with the mindset of a craftsman and the discipline of an engineer. The first step was to listen—to understand the nuances of the prototyping architecture, the pain points in the existing process, and the expectations of the customer’s team.

Together, they drafted detailed test specifications tailored for the NPI phase. These documents became the shared language of the project, aligning goals and setting the foundation for a smooth development journey. With clarity established, E-Sharp moved swiftly into execution.

The test development was multifaceted. Custom scripts were written to initialize and program the boards, including multi-stage sequences for the FPGAs. Drivers were developed for specific devices, such as power supply units, ensuring precise control and monitoring throughout the test cycle. Sequencing of the tests was integrated within NI TestStand, providing a structured approach to test execution.

But software was only half the story. The complexity of the boards demanded custom hardware interfaces—test boards that could adapt between the devices under test and the data acquisition system. E-Sharp’s in-house prototyping capabilities proved invaluable here, enabling rapid design iterations and tight integration with the test logic.

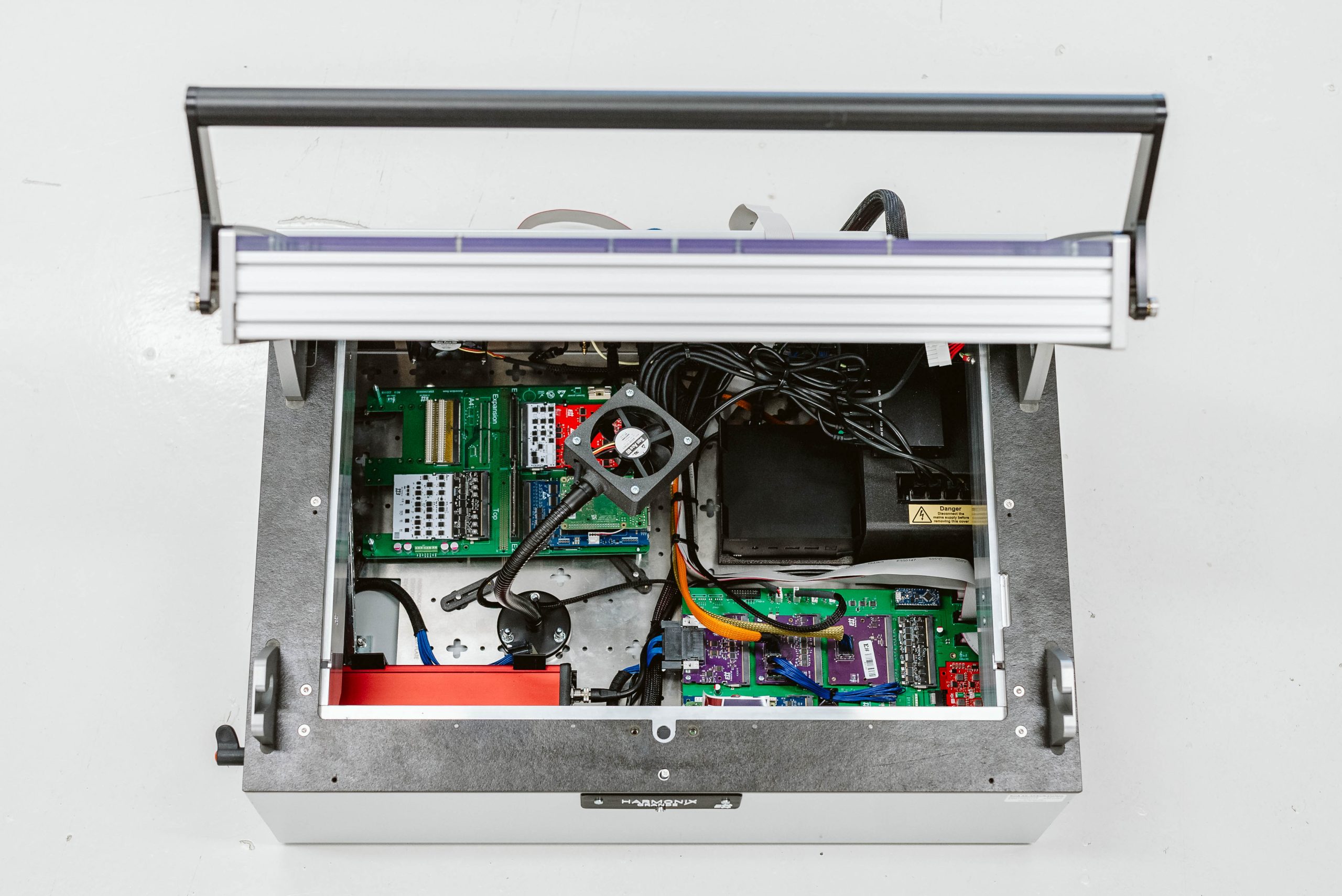

Then came the fixtures. E-Sharp introduced two groundbreaking concepts: Harmonix and Octave. Octave, in particular, featured a flip-jig mechanism and custom plugs capable of handling thousands of contacts. This innovation transformed the operator experience, allowing boards to be mounted and secured in seconds—a dramatic improvement over traditional methods.

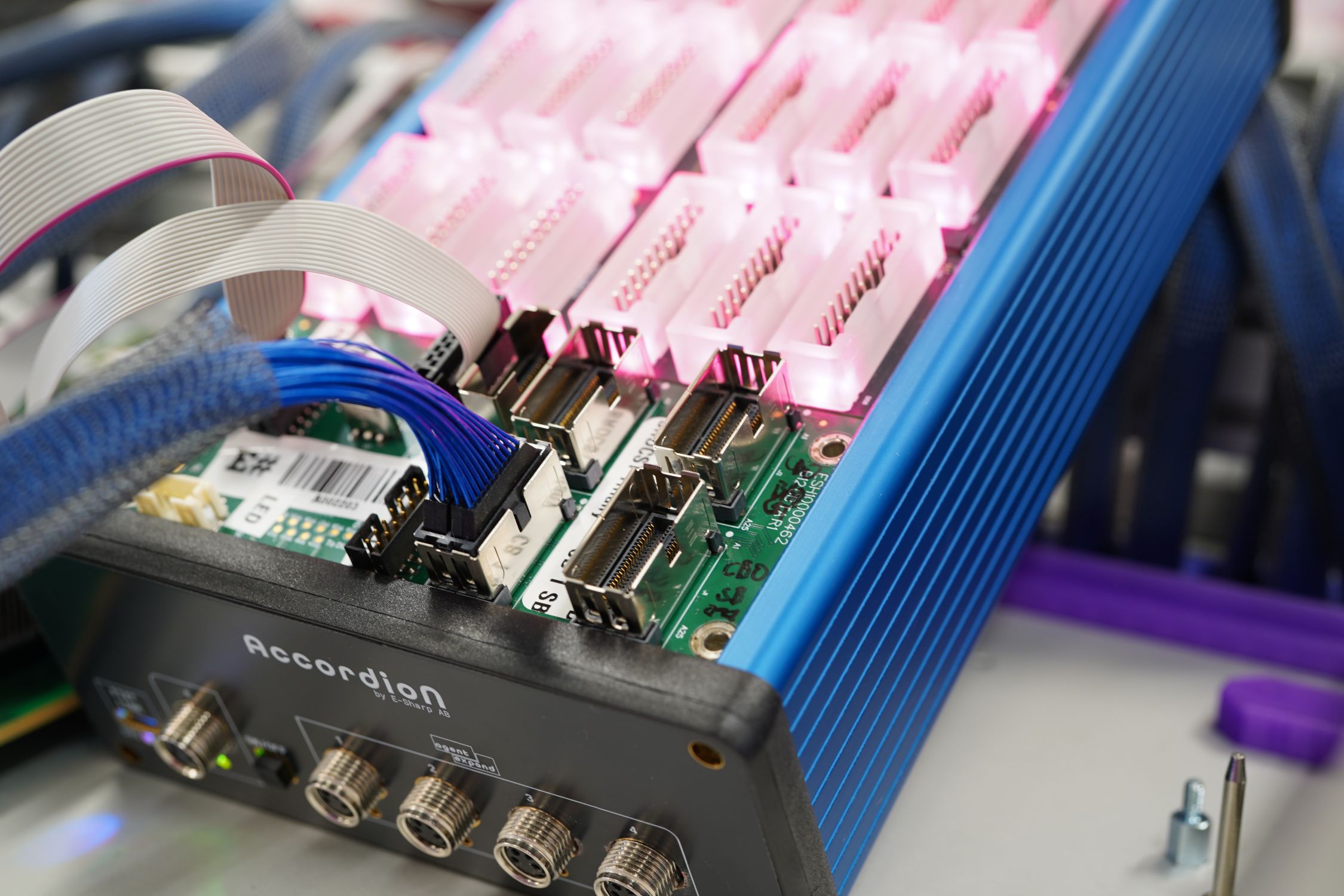

Data acquisition was handled by the Accordion Agent, now in its second generation. Fast, scalable, and intuitive, the Agent integrated seamlessly with TestStand and delivered real-time insights with minimal latency. The new version of the Agent reduced test execution time, enabling faster throughput without compromising accuracy.

Every test result was logged and stored in the customer’s manufacturing execution system (MES), ensuring full traceability. From the first signal check to the final pass/fail verdict, every step was documented, searchable, and auditable.

Results

The impact of E-Sharp’s solution is immediate and profound.

Testing becomes faster, more reliable, and more comprehensive. Faults are caught early, before boards reach the assembly line. Operators can mount and test boards with ease, thanks to the ergonomic design of the fixtures. And with every result stored in the MES, the customer gains a level of traceability that empowers both quality assurance and continuous improvement.

But beyond the metrics, what E-Sharp delivers is confidence. Confidence that every board entering a prototyping system is rigorously validated as part of the NPI process. Confidence that the test infrastructure can scale with future product generations. Confidence that the partnership is built not just on capability, but on trust.

This is not just a technical achievement. It is a transformation—of process, of mindset, and of possibility.

From prototype to production, our NPI service empowers engineers with clarity and confidence.

We design functional circuit tests using proven methods and our proprietary Accordion system for precise signal capture. With Octave and Harmonix platforms, we deliver adaptable, high-integrity environments. Our multidisciplinary team supports full test development — from drivers to station build — using tools like NI TestStand, Python, and C#. Trusted by global leaders and local pioneers.