Why

Accordion?

The Accordion framework is the result of decades of experience from designing hardware test interface applications. Every company that manufactures things have this challenge; the product needs to be tested one way or another. In many cases there are need for analog or digital signals/stimuli, different communication protocols such as I2C, SPI, UART, CAN, Modbus or USB. The product needs to be supplied with power, often with the need of testing the battery charging functionality. Sometimes the test rig needs to be powered as well.

Every product is unique, a test- and

measurement platform developed for one product is either too large (expensive)

for one application or too small and limited for another. Different voltage

ranges, special connectors and communication buses is the reason why companies

often ends up building a “special thing” each time and spends a lot of

engineering resources to do it.

With few established rules, test development can be made up from very specific custom test boards to things purchased on Ebay or AliExpress that creates all kinds of support issues and sourcing problems. Maintenance can be very tricky when years has passed and the parts can’t be sourced or the guy implementing it has left or is busy with the next big product.

Many companies goes through the same thing; when starting out, manufacturing test is made up by R&D tools and manual testing (often done by the R&D engineers themselves). After the realization that this hurts quality and consumes precious engineering resources, “Santa’s workshop” takes over and test solutions are built from a great mix of custom boards, purchased gadgets and Arduino’s. When the number of active products increases, this becomes unsustainable. Usually it all ends up with building the test solution on very expensive products/measurement equipment and creating a team dedicated to this task.

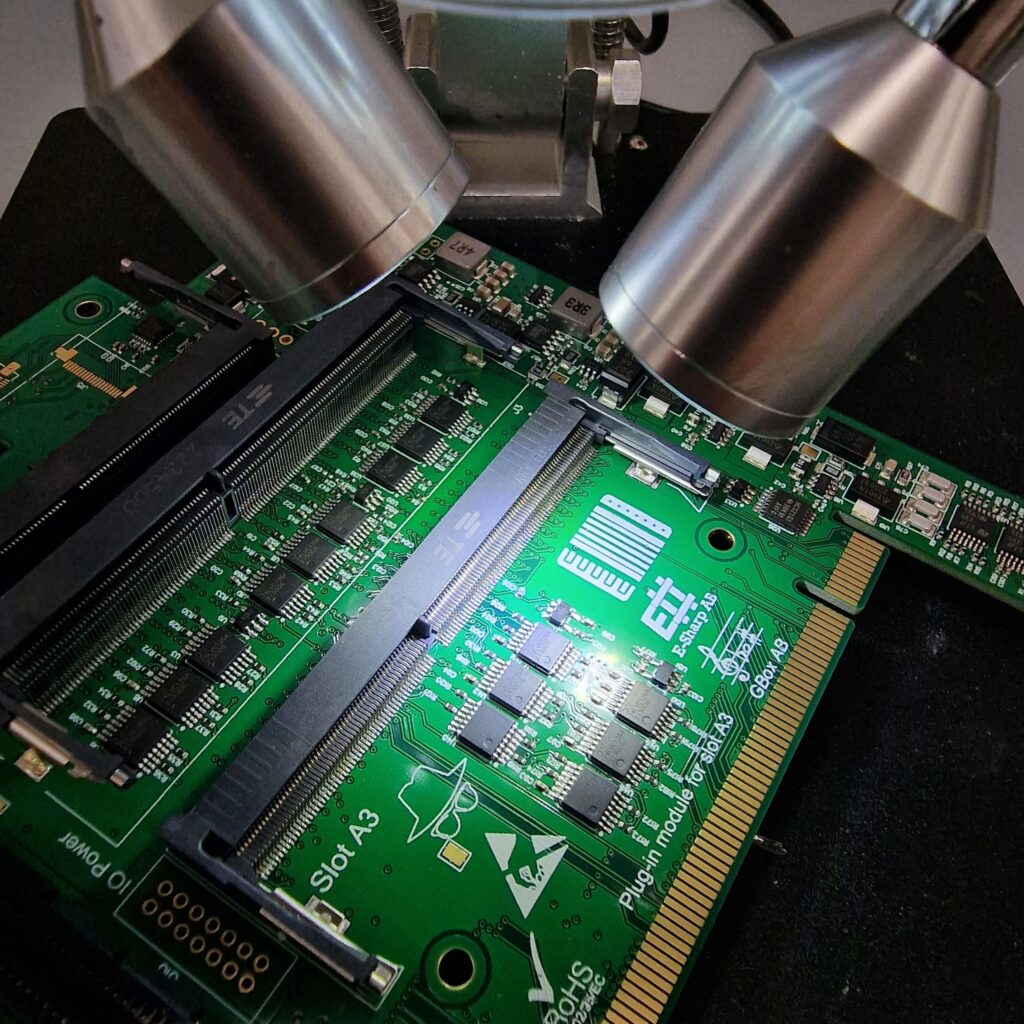

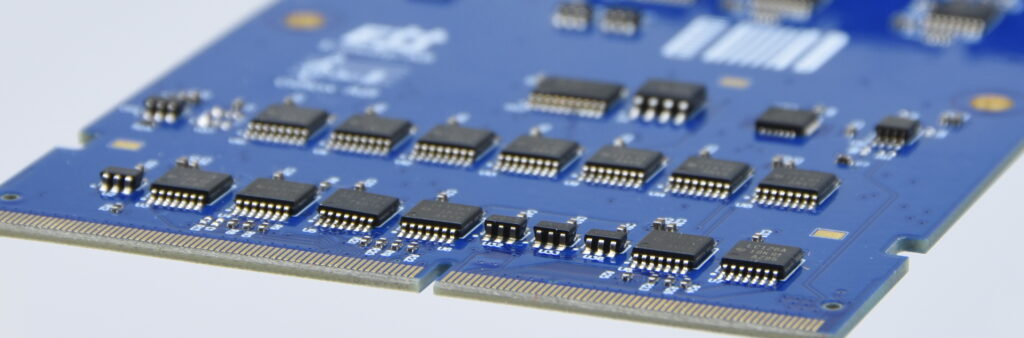

This is what makes Accordion™ special – we have thought about this for a long time and have come up with a flexible solution. Accordion™ is modular which means that every system can be equipped with exactly the functionality that is needed.

We have addressed the common problems and challenges one by one.

Challenge: How do I find the optimum capability of the test solution?

Solution: You can’t. The only way to win is not to play. Every attempt to make a solution large enough to cover all needs, there will soon be a product that needs more. The solution ends up being way to large/complicated/expensive for almost everything and too limited for a future product. In Accordion™, we provide scalability right from the start. The solution can be as small or large as you want. And when you realize that you need more capabilities, additional plug-in modules solve it

Challenge: How to make sure that I still can support manufacturing in 5-10 years from now?

Solution: There is no solution immune to end-of-life components or shortages. But the design approach in Accordion™ is built to be resilient. A component shortage doesn’t affect the whole product, a new module with equivalent functionality can be developed and the overall system functionality can be upheld as long as it is necessary.

Challenge: Our product is so special/unique, we have to develop a test solution ourselves.

Solution: Typically, this is not the case. Yes, the physical interface is often unique, which is why we don’t even attempt to implement the interface solution directly. With simple, often passive connector breakout boards we can interface virtually any product. We have the design capabilities to create that unique physical interface which bridges the gap between your product and Accordion™. But in most cases the communication buses, analog and digital signal functionality are similar.

It could of course happen that you need a

functionality that is not currently in our offering. However given the plug-in module concept we can develop it specifically for you or even introduce it in our standard offering. That’s what we love to do.

Challenge: We use Windows-based test computers (or Linux, or Mac, or …) and it has to work in our environment. We use Python/Labwiev/TestStand/C#/C++/Java and we need something that plugs straight in.

Solution: Of course! With Accordion™ REST-API based system, you can control it from any platform and from any programming language. What’s even better is that you can control Accordion™ from several applications at the same time, or even different computers.

Challenge: Our experience is that it’s really complicated to get things working when you buy something off the shelf. Especially as we use Mac (or Linux).

Solution: With Accordion™, it is easy. You could get started with a web browser only, without installing anything. Sure, we also provide porting drivers to .NET4.6.1, NET4.8 and NET6. NET6 can be run with full functionality on Windows, Linux and Mac.

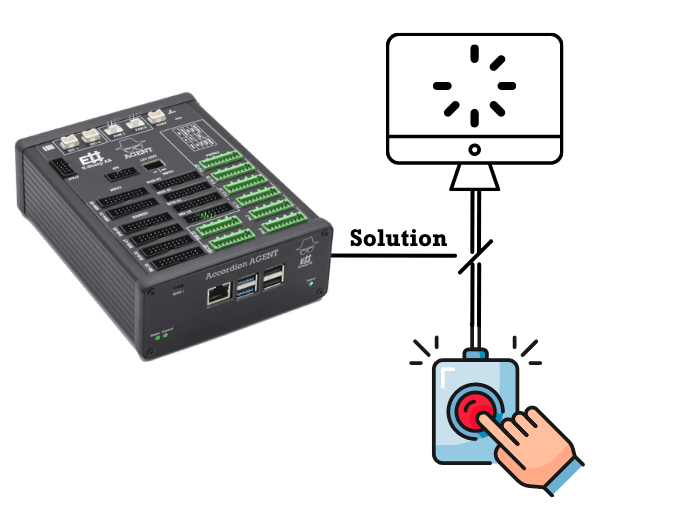

Challenge: We have a complicated test fixture and if the test hangs somewhere mid-test, the valves and actuators might come crashing into each other, destroying the fixture.

Solution: Don’t fret. Use the built-in State Machine Engine (SME) for your fixture control and you will have autonomous control over it, regardless of the state the test is in. Fixture features like “stop”-buttons, “open”-buttons or emergency stops will still work even if the test computer hangs.

Are there any other features that I should know about?

We think so. Here are a few less obvious features with the Accordion™ system:

It allows for shared debugging. Every seasoned test developer has been in the situation where a breakpoint is hit (or the test stops due to an error) and now you would really want to be able to read or alter one of the signals. But you can’t as the drivers towards the instruments and test interface is locked by the test system. With Accordion™, you can just fire up another application side by side to read or set signals and then continue the test as nothing happened. You can even do it from another computer.

It has 4 USB ports which can be used for a lot of things. We have for example implemented CAN bus and MODBUS communication devices that integrates into the same REST API driver structure.

It comes with a custom built application. The application AGENT UI is custom built and comes with every AGENT. With this application you can control everything from a single I/O to the graphs of the State Machine.

We have a wide range of standard breakout boxes and we are happy to design a special one for you. But you can always get started with a screw terminal breakout box.

You can get it with a DIN mount fastener

It has dual fan controllers built-in. This is excellent when you need cooling fans for your test fixture

The operating system that runs on the unit is Linux-based. So in case you need special functions, such as firewalls, communication to other networked equipment or that you want measurement data to be stored directly to your database system – we can fix it for you.